The project:

Ramp-up and Supply-Chain control improvement to reach desired production pace in New-Space business.

Our common success story

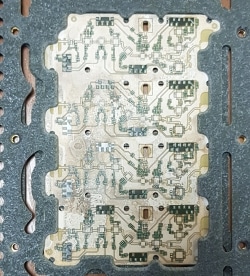

RF-X(1) is a reference SME for Radio Frequency devices especially for defense business. Following the closure of an important contract with a major player of space industry, RF-X have developed a ultra-compact, low-mass and low-consumption device to manage RF transmissions on board a satellite. The unprecedented production ramp-up of this complex piece of equipment raised vigilance from the final client, who tasked AppTek for the series delivery follow-up.

The challenge:

RF-X remarkable know-how it terms of design required a flawless execution on site and across the Supply-Chain. Moreover, the link with the client/end user had to be improved to avoid misunderstandings, clarify expectations, and above all, execute in due time. Only final assembly and performance tests were done in-house, while the sub-assemblies, including PCBA’s were manufactured outside. The whole chain had to ramp-up, while respecting tight cost/quality constraints.

The solution:

AppTek consultant first identified improvement tracks in Supply-Chain management and visited the tier-2 suppliers several times. Specifically, needs were clarified, as well as criteria, locations and inspection methods to reach a cost/efficiency optimum.

AppTek(s continuous presence on site allowed to set-up and maintain performance indicators for product and project, in order to focus the client’s and RF-X’s resources on high value-added tasks. These indicators, along with project tasks have been included in an Obeya, that AppTek first set-up and managed, before transferring its management to RF-X.

AppTek suggested, prototyped and built in co-operation with RF-X IT resources, production tracking methods, through agile methods (Scrum applied to lean manufacturing) that allowed to measure, thus improve production performance.

Finally, AppTek proposed an 18-month plan to industrial maturity, combining design methods update, with a focus on manufacturability, production organization through a partial digitalization, and strong managerial initiatives to re-inforce RF-X ability to co-engineering with their customers.

The results:

RF-X and their client have been particularly satisfied of AppTek’s mission that has followed for 18 months the production ramp-up. Our greatest pride remains that financing of this mission has been ensured equally: first by the client, then by RF-X, as an evidence of the trust and satisfaction of both parties.

(1) Name and pictures have been anonymized for the sake of confidentiality