RF-X – Leeds – United Kingdom

The project: Ramp-up and Supply-Chain control improvement to reach desired

AppTek was founded in 2011. Since our foundation, we have been honored of the trust of the biggest specialists in their fields, and our pride is to have served SME’s with the same professionalism. Our interventions have spanned over 3 continents.

We propose here below references and testimonies, as well as case studies based on real cases. Sometimes, for confidentiality reasons, names and figures are hidden.

The project: Ramp-up and Supply-Chain control improvement to reach desired

solar-mems.com The project:Design, development and production ramp-up of a robust,

The project:

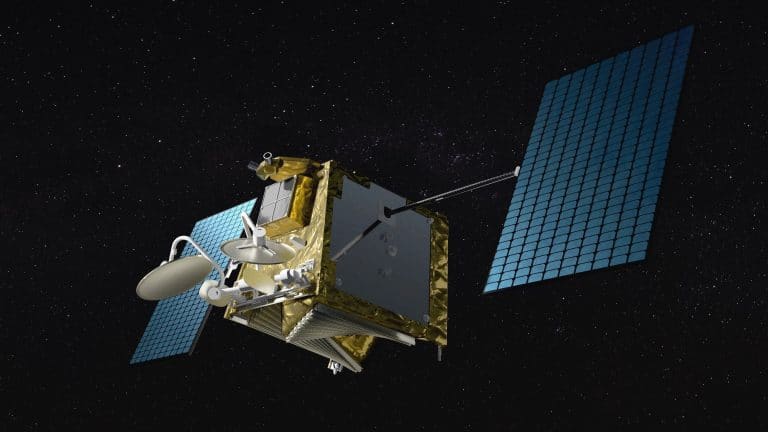

Design, development and production ramp-up of a robust, inexpensive and reliable Coarse Sun Sensor to be used as an attitude sensor for Low Earth Constellation satellites.

Our common success story:

Solar MEMS has a significant heritage in solar sensors, aimed mainly for photovoltaic energy efficiency optimization, and for space application from 2009. They designed the sensor, gathering their best practices, and heritage, optimizing all parameters to comply with the final user’s requirements.

The challenge:

The solution:

First a complete trustful relationship was built in a record time. Within less than 2 weeks, AppTek consultant was “part of the family” and participated in all project and board reviews. No issue was left in the dark and Solar MEMS team proactivity and transparence was key in success.

AppTek assisted Solar MEMS in building up reliable schedules for all tasks involved in the project, and especially introduced rigor and negotiation reflexes in relationships with both customer and key suppliers, in order to make the schedule resilient to unforeseen events, and guarantee the respect of deadlines.

A complete load/capacity assessment was made for internal production system, but also for key suppliers, with exhaustive identification of possible issues and bottlenecks. All workflows were systematically revisited to level them up to the necessary pace with a relevant safety factor.

In parallel, management methods based on agile processes were set-up to leverage human resources and have them providing the best: daily stand-up meeting, short validation loops, simplified reporting (internal and to the customer), involvement of suppliers through frequent visits. AppTek played a determinant role in bridging the cultural difference between the customer and Solar MEMS, and aligning the supply-chain to the necessary standards of quality and responsiveness.

The results:

Solar MEMS status as seen from the customer changed from a challenged position due to industrial readiness, to a recognized vendor, duly awarded by the customer among 40+ suppliers. Solar MEMS was never a source of delay on satellite manufacturing. This result allowed them to improve their pedigree in space business and be in position to touch new customers.

The project:

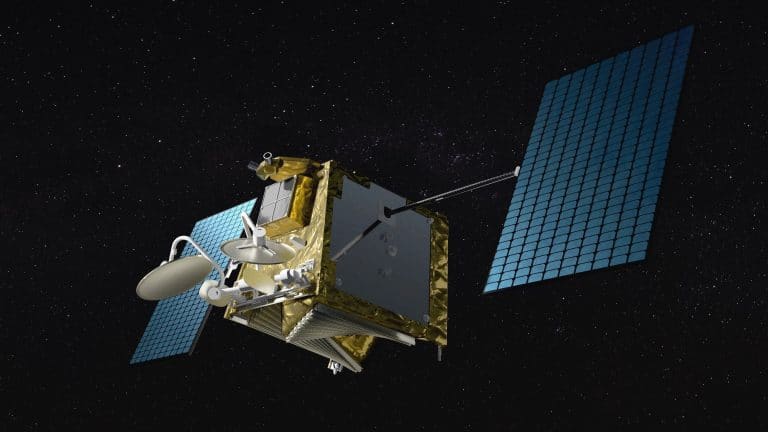

Design, development and production ramp-up of a robust, inexpensive and reliable Coarse Sun Sensor to be used as an attitude sensor for Low Earth Constellation satellites.

Our common success story:

Solar MEMS has a significant heritage in solar sensors, aimed mainly for photovoltaic energy efficiency optimization, and for space application from 2009. They designed the sensor, gathering their best practices, and heritage, optimizing all parameters to comply with the final user’s requirements.

The challenge:

The solution:

First a complete trustful relationship was built in a record time. Within less than 2 weeks, AppTek consultant was “part of the family” and participated in all project and board reviews. No issue was left in the dark and Solar MEMS team proactivity and transparence was key in success.

AppTek assisted Solar MEMS in building up reliable schedules for all tasks involved in the project, and especially introduced rigor and negotiation reflexes in relationships with both customer and key suppliers, in order to make the schedule resilient to unforeseen events, and guarantee the respect of deadlines.

A complete load/capacity assessment was made for internal production system, but also for key suppliers, with exhaustive identification of possible issues and bottlenecks. All workflows were systematically revisited to level them up to the necessary pace with a relevant safety factor.

In parallel, management methods based on agile processes were set-up to leverage human resources and have them providing the best: daily stand-up meeting, short validation loops, simplified reporting (internal and to the customer), involvement of suppliers through frequent visits. AppTek played a determinant role in bridging the cultural difference between the customer and Solar MEMS, and aligning the supply-chain to the necessary standards of quality and responsiveness.

The results:

Solar MEMS status as seen from the customer changed from a challenged position due to industrial readiness, to a recognized vendor, duly awarded by the customer among 40+ suppliers. Solar MEMS was never a source of delay on satellite manufacturing. This result allowed them to improve their pedigree in space business and be in position to touch new customers.

AppTek cooperate with major aerospace players (Safran, Airbus DS, Teledyne DS…) to industrialize their products. We have also worked with Alstom Grid (GE), and Siemens T&D to adapt their offer to the market. SME’s have used our services too, like Franklin/Duval-Messien (France), Easygrid (China), Coelme (Italy), Solarmems (Spain).